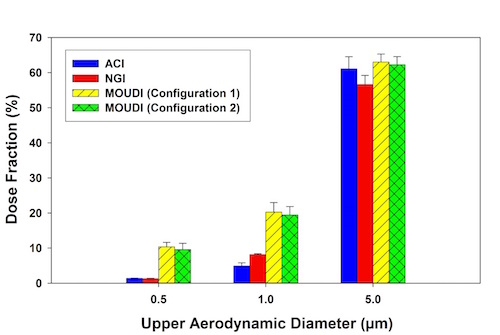

The Microorifice Uniform Deposit Impactor (MOUDI) is a relatively old impactor that we’ve found to be quite useful for the study of extrafine material. It has eight to ten stages in the sub-1 µm range so provides much more detail in this area. We’ve seen interesting results when comparing MOUDI, ACI and NGI data, with very different reported measurements of the fraction extrafine.

These impactors have quite different aerodynamic performance, optimized for differently sized particles, so this is perhaps unsurprising, but it does return us to the issue of how best to quantify how much extrafine is actually present. The MOUDI suggests far higher quantities than the other two impactors.

Figure 2: Measuring APSD with a MOUDI suggests that the fraction of extrafine in the dose is far higher than is indicated by measurements with the ACI and NGI

Q: What are the challenges for devices?

A: The challenge of dispersing particles down to the sub-5 µm range is sufficient for many, so going beyond that certainly calls for some rethinking with regards to the aerosolization technology we adopt. With DPIs the only energy to drive aerosolization is typically that provided by the inhalation action of the patient, so we need to think about technology that can make that energy work more effectively.

One of the innovations that we’ve had success with is the use of a breath actuated mechanism, (BAM) a technology that has been proposed for addressing the challenge of poor dose dispersion in compromised patient groups. A BAM incorporates a dose protector which restrains the dose until the pressure drop across the device reaches a certain figure. At this point the BAM mechanism triggers, the dose protector translocates, and the metered dose is aerosolized using the energy provided by the patient’s inhalation maneuver, under highly consistent conditions.